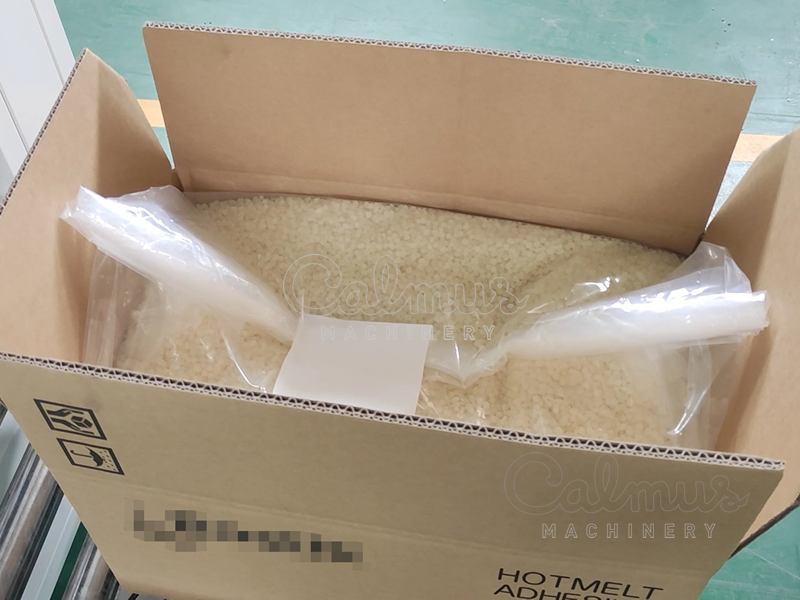

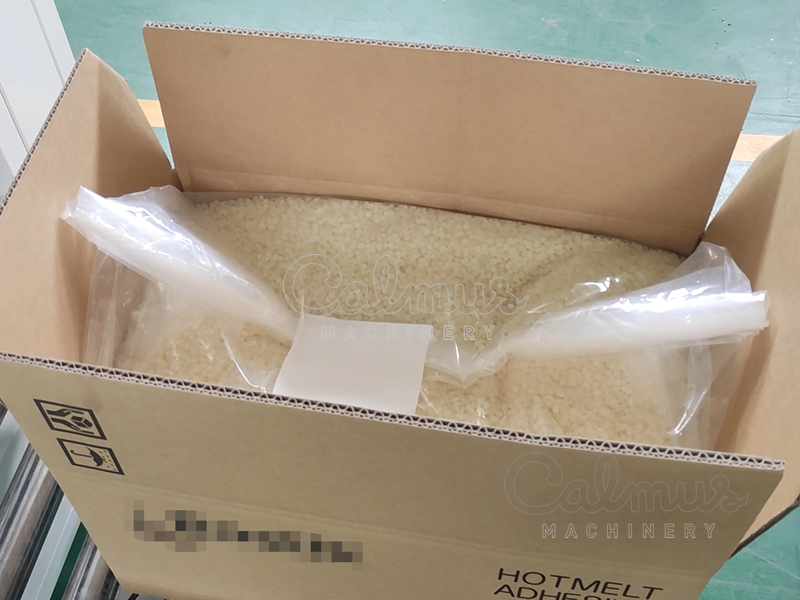

Bag-in-Box is the most common and an ideal bulk packaging solution for hot-melt glue pellets. A polyethylene bag as the liner inside the carton provides leak-proof containment for the pellets while preventing moisture ingress. The bag opening can be rolled up and secured with an adhesive label (instead of heat-sealing), allowing multiple retrievals when pellets remain after initial use.

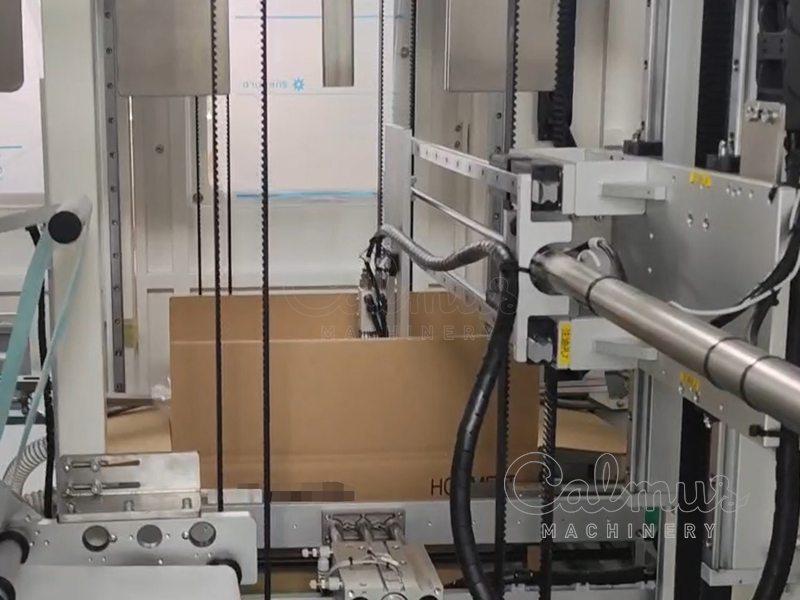

A carton erector and poly bag inserter work together to create lined boxes. The carton erector forms the boxes, then the bag inserter machine dispenses film from a roll, cuts and seals it into a bag, opens and cuffs the bag over the carton flaps, and uses air to expand the bag for a snug fit against the box walls.

Calmus Machinery’s bag uncuffer and top roller machines are designed to roll up bag tops inside boxes after hot-melt adhesive pellets are loaded. This bag uncuffer roller uncuffs the bag from the top flaps of the carton, stretches the bag opening, and applies a gentle vacuum to prevent ballooning. It then rolls up the top of the bag and applies a adhesive label to securely seal it, ensuring that products are securely packaged for storage or shipment. The machine can also be integrated with heat-sealing functionality upon request for additional versatility.

Seal the box top with a carton sealer to complete the bulk packaging process.

The following are the equipment units we manufactured for a world-leading hot-melt adhesive producer. The right one is a bag inserter machine, and the left one is a bag uncuffer and roller machine.

We also offer a bag uncuffer and top folder machine that folds (rather than rolls up) bag openings.