Form-Load-Seal 3-in-1 Case Packer | Side-Load Monoblock Cartoning Machine

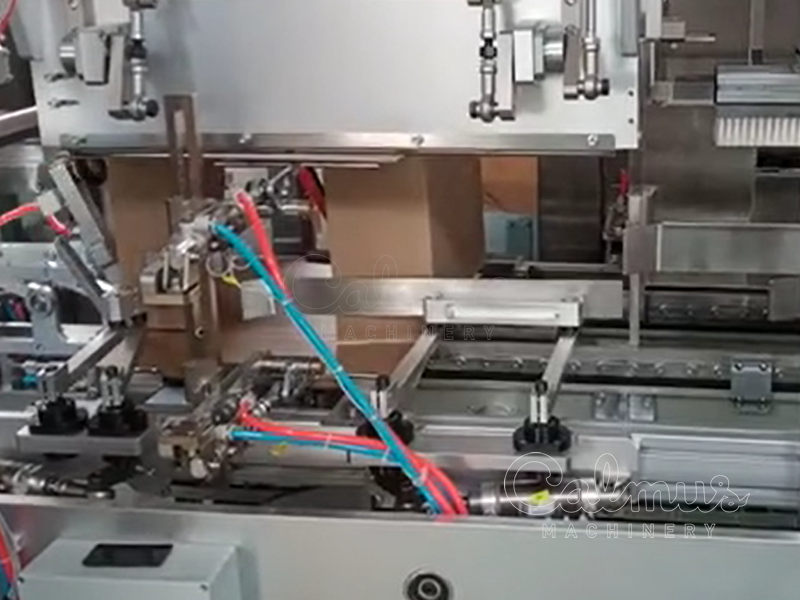

The side-load monoblock cartoning machine is a versatile form-load-seal 3-in-1 case packer system designed to streamline the entire process of case forming, product loading, and case sealing into one compact, integrated unit. It erects fold-flat carton blanks horizontally, conveys the cases to the loading station, closes the side flaps by folding them, sorts and groups infeed products, pushes them into the cases from the side, conveys the loaded cases to the sealing station, and seals both the tops and bottoms. Perfect for industries with high-speed packaging requirements, this innovative system offers a reliable and efficient solution for inserting brick-shaped products (like butter bricks and carton drinks), pouches, bags, and a variety of other shapes into corrugated cases with minimal labor and maximum speed.

This side-load case packer utilizes a pushing system that inserts products into cases from the sides. The system is capable of handling brick-shaped products, pouches, bags, and other similarly shaped items in multiple layers, optimizing both packing density and efficiency. Whether you are packaging food, pharmaceuticals, consumer goods, or electronics, this machine is designed to meet a wide range of packaging needs.

Thanks to its flexible design, the monoblock case packer can accommodate a wide variety of case sizes and pack patterns, making it a versatile choice for different product types. The cartons are securely sealed with either tape or hot-melt glue, providing a reliable seal to ensure product safety during transit and storage.

This form-load-seal 3-in-1 system integrates the key functions of carton forming, product insertion, and carton sealing into one compact, space-saving unit. The monoblock design eliminates the need for multiple machines, reducing overall floor space and simplifying your production process. With easy installation and minimal maintenance requirements, this system helps optimize production efficiency and reduces downtime in your packaging line.

Features:

1) Form-load-seal 3-in-1 design: compact footprint and easy installation.

2) Side-push loading for efficient case packing.

3) Pre-sorted product grouping before loading, facilitating the downstream cartoning process and increasing speed.

4) Adjustable carton blank storage shelf for quick changeovers.

5) Simple and smooth adjustment of the cartoning mechanism.

6) Control panel with PLC touchscreen display for user-friendly operation.

7) Alarms for material shortage, door opening, and faults.

8) Capable of speeds up to 25 boxes per minute.

9) Optional inkjet barcode printing and barcode recognition.

Specifications:

Packing type: side-load

Sealing media: tape or hot-melt glue

Compressed air: 6-8 bar

Power supply: 3-phase, customized voltage

Power consumption: 3 kW

System weight: 2,300 kg

System dimensions: L3,500 * W1,900 * H2,300 mm

In addition to brick-shaped products, this monoblock case packer can be customized to accommodate a wide range of products, including pouches, bags, and other irregularly shaped items. If your packaging needs are unique or involve complex product shapes, our team can work with you to design a customized solution that fits your requirements perfectly.